Containerized or Skid – Mounted

Our designs take advantage of clean and simple mill configurations to ensure your grout plant always operates at near or full capacity.

Amix Grout Plants (AGP) are advanced grout mixing and pumping systems. The AGP is built using modular design principles with a focus on ease of use and scalability. The AGP utilizes clean and simple mill configuration with less moving parts.

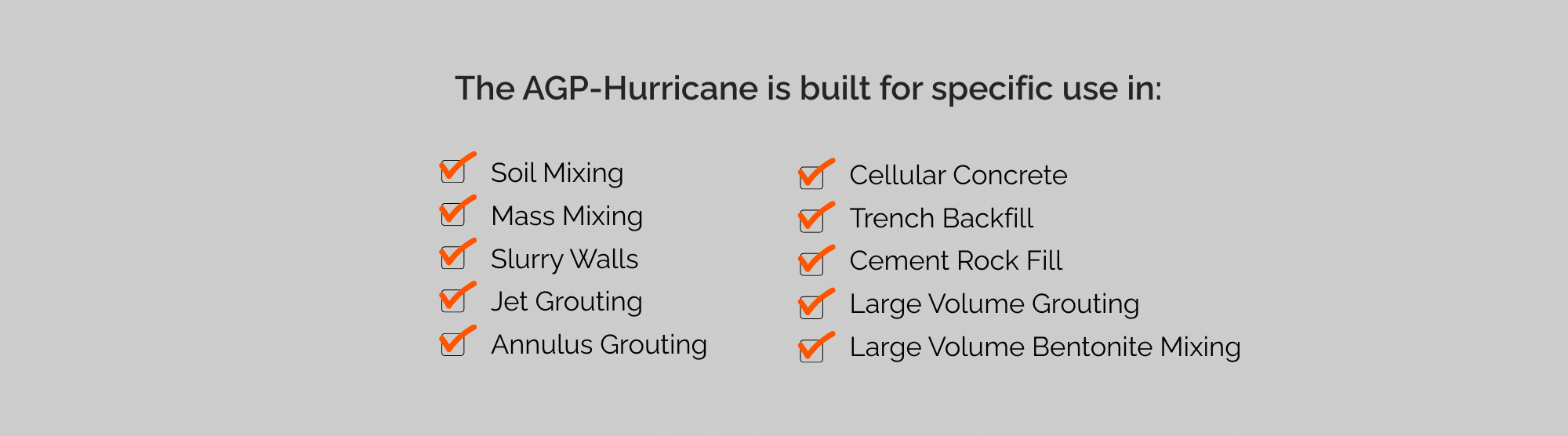

The AMIX Systems AGP Hurricane line of mixing plants is designed for high-output applications and can be customized for virtually any application. The AGP colloidal grout plants produce high outputs while maintaining a low carbon footprint.

The Hurricanes are self-cleaning, can operate 24/7 with the highest operational availability, low consumption of wear components and maintenance available on the market, period.

The AMIX Advantage

Our design advancements keep your plants operating at near 100% availability and are automated to free up personnel for other requirements.

It’s time to simplify your grout mixing process

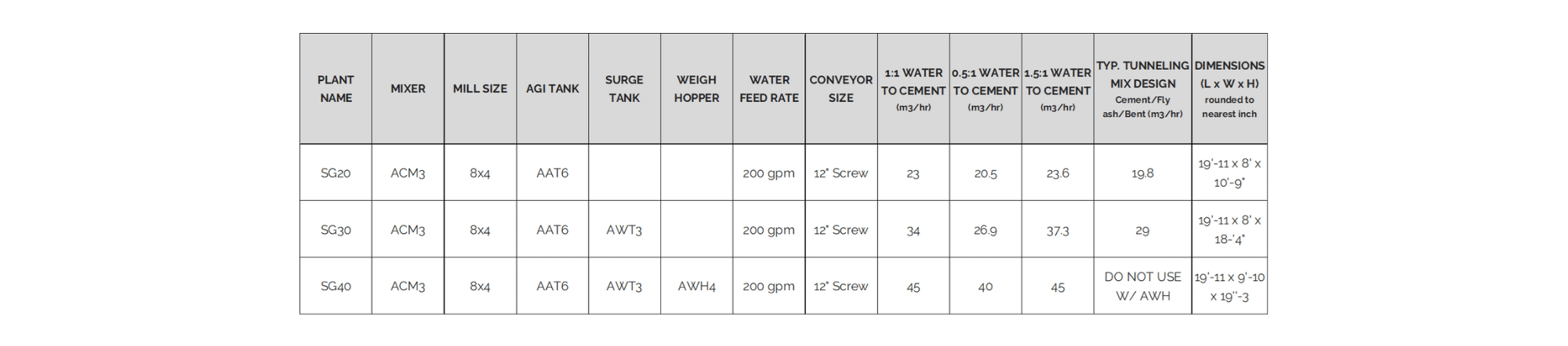

Specifications

AGP – Hurricane High Shear Mixing System

Max Output – 25 – 110+ m3/hr (110 – 480+ gpm)

Heavy-Duty 8/4E-MA High Shear Colloidal Mills

203 mm (8”) Inlet

102 mm (4”) Outlet

Max Output – 272 m3/hr

Max Flow – 1,200 gpm

Options & Uses

Containerized or Skid-Mounted

Grout Pumps

Agitation Tanks

Silos & Hoppers

Feed Systems

Screw Conveyors and other related material handling systems

Dust Collection

Admixture System

Diesel electric generator unit to power grout plant electrical system

Get a quote

If you would like to learn more about this product and receive a quote simple fill out our quote request form.

Email: sales@amixsystems.com – Phone: 1-604-746-0555

Postal Address: Suite 460 – 688 West Hastings St Vancvouver, BC V6B 1P1